Vol. 149, No. 3 — February 11, 2015

Registration

SOR/2015-17 January 30, 2015

HAZARDOUS PRODUCTS ACT

Hazardous Products Regulations

P.C. 2015-40 January 29, 2015

Whereas, pursuant to section 19 (see footnote a) of the Hazardous Products Act (see footnote b), the Minister of Health has consulted with the government of each province and with the organizations representative of workers, organizations representative of employers and organizations representative of suppliers that the Minister considers appropriate;

Therefore, His Excellency the Governor General in Council, on the recommendation of the Minister of Health, pursuant to subsection 15(1) (see footnote c) of the Hazardous Products Act (see footnote d), makes the annexed Hazardous Products Regulations.

HAZARDOUS PRODUCTS REGULATIONS

PART 1

INTERPRETATION

Definitions

1. (1) The following definitions apply in these Regulations.

“Act”

« Loi »

“Act” means the Hazardous Products Act.

“aerosol dispenser”

« générateur d’aérosol »

“aerosol dispenser” means a non-refillable receptacle made of metal, glass or plastic and containing a gas that is compressed, liquefied or dissolved under pressure, with or without a liquid, foam, mousse, paste, gel or powder, and fitted with a release device allowing the contents to be ejected in the form of solid or liquid particles in suspension in a gas, as a foam, mousse, paste, gel or powder or in a liquid or gaseous state.

“ATE”

« ETA »

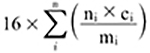

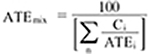

“ATE” means an acute toxicity estimate, and includes the LD50 and the LC50, and the acute toxicity point estimate determined in accordance with the table to section 8.1.7.

“CAS registry number”

« numéro d’enregistrement CAS »

“CAS registry number” means the identification number assigned to a chemical by the Chemical Abstracts Service, a division of the American Chemical Society.

“chemical name”

« dénomination chimique »

“chemical name” means a scientific designation of a material or substance that is made in accordance with the rules of nomenclature of either the Chemical Abstracts Service, a division of the American Chemical Society, or the International Union of Pure and Applied Chemistry, or a scientific designation of a material or substance that is internationally recognized and that clearly identifies the material or substance.

“flash point”

« point d’éclair »

“flash point” means the lowest temperature, corrected to the standard pressure of 101.3 kPa, at which the application of an ignition source causes the vapours of a liquid to ignite.

“gas”

« gaz »

“gas” means a mixture or substance that

- (a) at 50°C has an absolute vapour pressure of greater than 300 kPa; or

- (b) is completely gaseous at 20°C and at the standard pressure of 101.3 kPa.

“GHS”

« SGH »

“GHS” means the United Nations document entitled Globally Harmonized System of Classification and Labelling of Chemicals (GHS), Fifth Revised Edition.

“hazardous ingredient”

« ingrédient dangereux »

“hazardous ingredient” means an ingredient in a mixture that, when evaluated as an individual substance, is classified in a category or subcategory of a health hazard class.

“hazard statement”

« mention de danger »

“hazard statement” means a phrase assigned to a category or subcategory of a hazard class or, in the case of column 5 of Parts 4 to 6 of Schedule 5, the required statement that describes the nature of the hazard presented by a hazardous product.

“initial boiling point”

« point d’ébullition initial »

“initial boiling point” means the temperature of a liquid at which its vapour pressure is equal to the standard pressure of 101.3 kPa, i.e., the temperature at which the first gas bubble appears.

“initial supplier identifier”

« identificateur du fournisseur initial »

“initial supplier identifier” means the name, address and telephone number of

- (a) the manufacturer; or

- (b) the importer of the hazardous product who operates in Canada.

“LC50”

« CL50 »

“LC50” means the concentration of a mixture or substance in air that causes the death of 50.0% of a group of test animals.

“LD50”

« DL50 »

“LD50” means the single dose of a mixture or substance that, when administered by a particular exposure route in an animal study, is expected to cause the death of 50.0% of a given animal population.

“liquid”

« liquide »

“liquid” means a mixture or substance that

- (a) at 50°C has a vapour pressure of 300 kPa or less;

- (b) is not completely gaseous at 20°C and at the standard pressure of 101.3 kPa; and

- (c) has a melting point or initial melting point of 20°C or less at the standard pressure of 101.3 kPa or, in the case of a mixture or substance for which neither can be determined, is shown

- (i) to be a liquid as a result of the ASTM International method ASTM D4359-90, entitled Standard Test Method for Determining Whether a Material Is a Liquid or a Solid, as amended from time to time, or

- (ii) to not be pasty as a result of the test for determining fluidity (penetrometer test), referred to in section 4 of chapter 3 of Part 2, numbered 2.3.4, of Annex A of the European Agreement Concerning the International Carriage of Dangerous Goods by Road, as amended from time to time.

“Manual of Tests and Criteria”

« Manuel d’épreuves et de critères »

“Manual of Tests and Criteria” means the United Nations document entitled Recommendations on the Transport of Dangerous Goods: Manual of Tests and Criteria, as amended from time to time.

“manufacturer”

« fabricant »

“manufacturer” means a supplier who, in the course of business in Canada, manufactures, produces, processes, packages or labels a hazardous product and sells it.

“OECD”

« OCDE »

“OECD” means the Organisation for Economic Co-operation and Development.

“outer container”

« contenant externe »

“outer container” means the most outward container of a hazardous product that is visible under normal conditions of handling, but does not include the most outward container if it is the only container of the hazardous product.

“pictogram”

« pictogramme »

“pictogram” means a graphical composition that includes a symbol along with other graphical elements, such as a border or background colour.

“precautionary statement”

« conseil de prudence »

“precautionary statement” means a phrase that describes the recommended measures to take in order to minimize or prevent adverse effects resulting from exposure to a hazardous product or resulting from improper storage or handling of a hazardous product.

“product identifier”

« identificateur de produit »

“product identifier” means, in respect of a hazardous product, the brand name, chemical name, common name, generic name or trade name.

“risk group classification”

« classification par groupe de risque »

“risk group classification” means, in relation to the “Biohazardous Infectious Materials” health hazard class, classification in Risk Group 2, Risk Group 3 or Risk Group 4 as defined in subsection 3(1) of the Human Pathogens and Toxins Act.

“SADT” or

“self- accelerating decomposition temperature”

« TDAA » ou

« température de décomposition autoaccélérée »

“SADT” or “self-accelerating decomposition temperature” means the lowest temperature at which self-accelerating decomposition occurs.

“scientifically validated method”

« méthode validée sur le plan scientifique »

“scientifically validated method” means, in relation to a hazard, a method that specifies standards for the evaluation of that hazard and whose results are accurate and reproducible, in accordance with established scientific principles.

“signal word”

« mention d’avertissement »

“signal word” means, in respect of a hazardous product, the word “Danger” or “Warning” that is used to alert the reader to a potential hazard and to indicate its severity.

“solid”

« solide »

“solid” means a mixture or substance that is not a liquid or gas.

“United Nations Model Regulations”

« Règlement type des Nations Unies »

“United Nations Model Regulations” means the United Nations document entitled Recommendations on the Transport of Dangerous Goods: Model Regulations, as amended from time to time.

“UN number”

« numéro ONU »

“UN number” means the four-digit identification number issued in accordance with the United Nations Model Regulations.

“vapour”

« vapeur »

“vapour” means the gaseous form of a mixture or substance released from its liquid or solid state.

“work place”

« lieu de travail »

“work place” means a place where a person works for remuneration.

Reference to hazard class

(2) In these Regulations, a reference to a hazard class is to be read as a reference to a hazard class that is listed in Schedule 2 to the Act.

Health professionals

(3) For the purposes of Parts 5 and 6, health professionals are

- (a) physicians who are registered, and entitled under the laws of a province to practise medicine and who are practising medicine under those laws in that province; and

- (b) nurses who are registered or licensed, and entitled under the laws of a province to practise nursing and who are practising nursing under those laws in that province.

Interpretation of “should”

(4) When the word “should” is used in a text that is referenced or incorporated by reference in these Regulations, it is to be read as imperative, unless the context requires otherwise.

PART 2

CLASSIFICATION OF A PRODUCT, MIXTURE, MATERIAL OR SUBSTANCE

GENERAL

Order of decreasing severity

2. (1) In each Subpart of Parts 7 and 8, the categories and subcategories in each of the classification tables to those Subparts are set out in the order of the hazard’s decreasing severity, except for the categories of the classification table to Subpart 5 of Part 7.

Evaluation — more severe hazard

(2) If a product, mixture, material or substance has been evaluated in accordance with the criteria and requirements of a category or subcategory of a hazard class that represents the more severe hazard in a classification table compared to another category or subcategory of that hazard class in the same classification table and is classified in that category or subcategory, the product, mixture, material or substance need not be evaluated in respect of a category or subcategory of the same classification table of the same hazard class that represents a less severe hazard.

Prescribed classification

(3) Subject to subsections (4) and (5), any product, mixture, material or substance for which classification in a category or subcategory of a hazard class is prescribed in Schedule 4 is classified in that category or subcategory. The product, mixture, material or substance must also be evaluated in accordance with section 2.1, 2.2 or 2.7 in respect of each of the categories or subcategories of the other hazard classes.

Ingredient — more severe hazard

(4) If a product, mixture, material or substance is one for which classification in a category or subcategory of a hazard class is prescribed in Schedule 4, and if it has been mixed with one or more ingredients that are classified in a category or subcategory of the same classification table of the same hazard class that represents a more severe hazard, the mixture as a whole must be classified in the category or subcategory that represents the more severe hazard.

Prescribed classification — Subpart 1, 4, 7 or 8 of Part 8

(5) A mixture, material or substance — for which classification in a category or subcategory of a classification table of a hazard class set out in Subpart 1, 4, 7 or 8 of Part 8 is prescribed in Schedule 4 — must also be evaluated in accordance with section 2.1 or 2.2, in the case of Subpart 1, 4 or 7 of Part 8, in respect of each of the categories or subcategories of the other classification tables of the same hazard class, and in the case of Subpart 8 of Part 8, in respect of each of the categories of the same classification table.

Impurities, stabilizing solvents and stabilizing additives — substance

(6) Any impurities, stabilizing solvents or stabilizing additives that are known to the supplier to be present in a substance and that are classified must be considered for the purpose of classification of the substance if they are present at a concentration above the concentration limit for an ingredient in a mixture set out in a particular category or subcategory of any hazard class.

Impurities, stabilizing solvents and stabilizing additives — mixture

(7) Any impurities, stabilizing solvents or stabilizing additives that are known to the supplier to be present in a mixture and that are classified must be considered for the purpose of classification of the mixture if they are present at a concentration above the concentration limit for an ingredient in a mixture set out in a particular category or subcategory of any hazard class.

Individually packaged in outer container

(8) If two or more different and individually packaged products, mixtures, materials or substances, designed to be accessed individually, are packaged together in an outer container for sale or importation, the assemblage of the products, mixtures, materials and substances in the outer container must not be considered as a single product for the purpose of classification, as each product, mixture, material or substance is subject to the classification provisions of this Part.

Animal data — not relevant to humans

(9) Animal data that demonstrate conclusively, based on established scientific principles, that the mechanism or mode of action of the substance or mixture in animals is not relevant to humans must not be used for the purpose of classifying a substance or mixture in any of the health hazard classes referred to in Subparts 1 to 10 and 12 of Part 8.

MATERIAL OR SUBSTANCE

Classification — material or substance

2.1. Subject to sections 2.8 and 2.9, for the purpose of establishing whether a material or substance is classified in a category or subcategory of a hazard class, the material or substance must be evaluated in accordance with established scientific principles, with respect to the criteria and requirements of each category or subcategory of the hazard class as set out in Parts 7 and 8, using available data of the following types, as applicable:

- (a) in relation to the material or substance itself,

- (i) results of testing or studies carried out in accordance with the test methods referred to in Part 7 or 8,

- (ii) results of testing or studies carried out in accordance with generally accepted standards of good scientific practice at the time the test or study was carried out,

- (iii) conclusions based on established scientific principles, and

- (iv) case reports or documented observations; and

- (b) except for Subparts 2 and 3 of Part 8, if the data of the types referred to in paragraph (a) are insufficient to evaluate the material or substance in accordance with the criteria and requirements set out in Parts 7 and 8, in relation to a material or substance that has similar properties,

- (i) results of testing or studies carried out in accordance with the test methods referred to in Part 7 or 8,

- (ii) results of testing or studies carried out in accordance with generally accepted standards of good scientific practice at the time the test or study was carried out,

- (iii) conclusions based on established scientific principles, and

- (iv) case reports or documented observations.

MIXTURE

Classification

Part 7

2.2. (1) Subject to section 2.8, for the purpose of establishing whether a mixture is classified in a category or subcategory of a physical hazard class, the mixture must be evaluated, in respect of each category or subcategory of each physical hazard class, using data of the types referred to in subparagraphs 2.1(a)(i) to (iv) in relation to the mixture or, if the data of those types are insufficient to evaluate the mixture in accordance with the criteria and requirements set out in Part 7, using data of the types referred to in subparagraphs 2.1(b)(i) to (iv) in relation to a mixture with similar properties.

Part 8

(2) Subject to section 2.9, for the purpose of establishing whether a mixture is classified in a category or subcategory of a health hazard class, the mixture must be evaluated, in respect of each category or subcategory of each health hazard class, using data of the types referred to in subparagraphs 2.1(a)(i) to (iv), in relation to the ingredients, the mixture as a whole or a mixture with similar properties, following the order of the provisions, in relation to mixtures, as presented in each Subpart of Part 8.

Part 8 — order of provisions

(3) When following the order of the provisions in accordance with subsection (2), the mixture must be classified in accordance with the first provision that permits its classification. Once the mixture is classified, the provisions that follow within the same Subpart in relation to mixtures do not apply, except in the case of Subparts 1, 4, 7 and 8 of Part 8.

Bridging Principles

Definitions

2.3. (1) The following definitions apply in this section.

“production batch”

« lot de fabrication »

“production batch” means a batch that results from a consistent production process using fixed physico-chemical parameters when there is no intention to alter the characteristics of the final product.

“tested”

« testé »

“tested” refers to a mixture for which there are data of a type referred to in subparagraph 2.1(a)(i), (ii) or (iv).

Application of bridging principles

(2) In the case of the health hazard classes set out in Subparts 1 to 10 of Part 8, the bridging principles set out in subsections (3) to (8) must be applied if there is an indication to that effect.

Dilution

(3) If a tested mixture that is classified in a category or subcategory of a health hazard class set out in Subparts 1 to 10 of Part 8 is diluted with a diluent, the following applies provided that the diluent is a mixture or substance that, with respect to that health hazard class, has an equivalent or less severe hazard classification than the least hazardous ingredient of the tested mixture and, based on established scientific principles, does not affect the classification of the tested mixture:

- (a) in the case of a tested mixture that is classified in a category or subcategory of a health hazard class set out in Subparts 1 to 3 of Part 8, either the method referred to in section 8.1.5, 8.2.11 or 8.3.11, as the case may be, must be used to establish whether the diluted mixture must be classified in a category or subcategory of a hazard class, or the diluted mixture must be classified in the same category or subcategory of the health hazard class as the tested mixture; or

- (b) in all other cases, the diluted mixture must be classified in the same category or subcategory of the health hazard class as the tested mixture.

Production batches

(4) The classification is the same for a mixture in all production batches of that mixture that are manufactured, produced or processed by the same supplier, unless there is a significant variation between the batches that affects the classification of the mixture.

Increase in concentration of hazardous ingredient

(5) If the concentration of a hazardous ingredient of a tested mixture is increased, the following applies:

- (a) in the case of the health hazard classes set out in Subparts 1, 4 and 8 to 10 of Part 8, if the tested mixture is classified in the Category 1 category of the health hazard class, the new mixture resulting from the increased concentration must be classified in the same category of the same health hazard class, without additional evaluation with regard to that hazard class;

- (b) in the case of the health hazard class set out in Subpart 2 of Part 8,

- (i) if the tested mixture is classified in the Category 1A subcategory of the health hazard class, the new mixture resulting from the increased concentration must be classified in the same subcategory of the same health hazard class, without additional evaluation with regard to that hazard class, or

- (ii) if the tested mixture does not contain any hazardous ingredient classified in the Category 1 category and is classified in the Category 2 category of the health hazard class, the new mixture resulting from the increased concentration must be classified in the same category of the same health hazard class, without additional evaluation with regard to that hazard class; and

- (c) in the case of the health hazard class set out in Subpart 3 of Part 8,

- (i) if the tested mixture is classified in the Category 1 category of the health hazard class, the new mixture resulting from the increased concentration must be classified in the same category of the same health hazard class, without additional evaluation with regard to that hazard class, or

- (ii) if the tested mixture does not contain any hazardous ingredient classified in the Category 1 category and is classified in the Category 2A subcategory of the health hazard class, the new mixture resulting from the increased concentration must be classified in the same subcategory of the same health hazard class, without additional evaluation with regard to that hazard class.

Interpolation

(6) In the case of the health hazard classes set out in Subparts 1 to 4 and 8 to 10 of Part 8, when three mixtures (A, B and C) contain identical ingredients — some or all of which are hazardous — if mixtures A and B have been tested and are classified in the same category or subcategory of the same health hazard class and if mixture C has not been tested and has the same hazardous ingredients as mixtures A and B with concentrations intermediate to the concentrations of those hazardous ingredients in mixtures A and B, then mixture C must be classified in the same category or subcategory of the same health hazard class as mixtures A and B.

Substantially similar mixtures

(7) If one of the mixtures (ingredient A + ingredient B) or (ingredient C + ingredient B) is a tested mixture that is classified in a category or subcategory of a health hazard class, the other mixture must be classified in the same category or subcategory of the same health hazard class if the following conditions are met:

- (a) the concentration of ingredient B is the same in both mixtures;

- (b) the concentration of ingredient A is the same as that of ingredient C; and

- (c) ingredients A and C are classified in the same category or subcategory of the same health hazard class and, based on established scientific principles, do not affect the classification of ingredient B.

Aerosols — health hazard classes

(8) In the case of the health hazard classes set out in Subparts 1 to 4, 8 and 9 of Part 8, a mixture to which a propellant has been added and that is contained in an aerosol dispenser must be classified in the same category or subcategory of the same health hazard class as the mixture to which no propellant was added if, based on established scientific principles, the added propellant does not affect the classification of the mixture on spraying.

Other Principles

Synergistic effects

2.4. (1) In order to establish whether a mixture is classified in a category or subcategory of a health hazard class, if the evaluation of the mixture is carried out in accordance with a provision that requires the use of data available on the ingredients in the mixture, then all data available on the potential occurrence of synergistic effects among the ingredients of the mixture must be used in the evaluation carried out in accordance with section 2.2.

Antagonistic effects

(2) If antagonistic effects among the ingredients of the mixture are considered in order to establish the classification of the mixture in a category or subcategory of a health hazard class in the course of the evaluation carried out in accordance with section 2.2, the data in respect of the antagonistic effects must be conclusive, based on established scientific principles.

Concentration limits — lower concentration

2.5. (1) In the case of Subparts 1 to 10 and 12 of Part 8, if an ingredient is present in a mixture at a lower concentration than the concentration limit for a particular category or subcategory of a health hazard class, but still presents the hazard identified by the category or subcategory of that hazard class at that concentration, the mixture must be classified in that category or subcategory.

Concentration limits — equivalent or higher concentration

(2) In the case of Subparts 1 to 10 and 12 of Part 8, subject to subsection 2.4(1), if an ingredient is present in a mixture at an equivalent or higher concentration than the concentration limit for a particular category or subcategory of a health hazard class, but further to evidence based on established scientific principles it does not present the hazard identified by the category or subcategory of that hazard class at that concentration, the mixture need not be classified in that category or subcategory in relation to that specific ingredient.

Maximum concentration

2.6. If a mixture with a specific product identifier contains a hazardous ingredient that is not always present at the same concentration, the maximum concentration must be used for the purposes of establishing whether the mixture is classified in a category or subcategory of a health hazard class.

PRODUCT

Classification — product

2.7. Subject to section 2.8, to establish whether a product is classified in a category or subcategory of a physical hazard class, it must be evaluated in accordance with section 2.1 or 2.2.

SPECIFIC RULES

Solids

2.8. In the case of the physical hazard classes set out in Subparts 7, 10 to 12 and 14 of Part 7, the data used for the purposes of evaluation of a solid must relate to the solid in the physical form in which it is sold or imported. If the solid is in a physical form that is different from that used to generate the data and the solid in that physical form is liable to display different behaviour, the solid must also be evaluated in that other physical form.

Biological availability

2.9. If it can be shown by conclusive experimental data from scientifically validated methods that the mixture, material or substance is not biologically available, it need not be classified in any health hazard class.

PART 3

LABELLING

Information elements

3. (1) Subject to section 3.6 and for the purposes of paragraphs 13(1)(b) and 14(b) of the Act, the label of a hazardous product or the container in which the hazardous product is packaged must provide, in respect of the hazardous product, the following information elements:

- (a) the product identifier;

- (b) the initial supplier identifier;

- (c) subject to subsections (2) to (5), for each category or subcategory in which the hazardous product is classified, with the exception of the categories referred to in paragraph (d), the information elements, namely, the symbol, signal word, hazard statement and precautionary statement, that are specified for that category or subcategory in section 3 of Annex 3 of the GHS;

- (d) subject to subsections (2) to (4), for each category set out in Subparts 17 to 20 of Part 7 and in Subparts 11 and 12 of Part 8 in which the hazardous product is classified,

- (i) the information elements that are specified for that category in Schedule 5, and

- (ii) any precautionary statements that are applicable to the hazardous product in terms of

- (A) general precautionary statements,

- (B) prevention precautionary statements,

- (C) response precautionary statements,

- (D) storage precautionary statements, and

- (E) disposal precautionary statements;

- (e) in the case of a hazardous product classified in a category of Subpart 1 of Part 8 and to which paragraph 8.1.6(b) applies, the supplemental label element “[Insert the total concentration in percentage of ingredients with unknown acute toxicity] % of the mixture consists of an ingredient or ingredients of unknown acute toxicity/[Insérez la concentration totale en pourcentage d’ingrédients ayant une toxicité aiguë inconnue] % du mélange consiste en ingrédients de toxicité aiguë inconnue”; and

- (f) in the case of a hazardous product that is classified as an acute toxicant and that, upon contact with water, releases a gaseous substance that has an LC50 that falls into one of the ranges indicated in Table 3 to subsection 8.1.1(3), the supplemental label elements that consist of the following hazard statements:

- (i) in the case of Categories 1 and 2, “In contact with water, releases gases which are fatal if inhaled/Au contact de l’eau, libère des gaz mortels en cas d’inhalation”,

- (ii) in the case of Category 3, “In contact with water, releases gases which are toxic if inhaled/Au contact de l’eau, libère des gaz toxiques en cas d’inhalation”, or

- (iii) in the case of Category 4, “In contact with water, releases gases which are harmful if inhaled/Au contact de l’eau, libère des gaz nocifs en cas d’inhalation”.

Codes or instructions

(2) The information elements required by paragraph (1)(c) need not include alphanumeric codes and the information elements required by paragraphs (1)(c) and (d) must not include instructions that are for the exclusive use of the competent authority, as defined in the GHS, or the supplier.

Substitution by pictogram

(3) The pictogram associated with a symbol in Schedule 3 must be substituted for the symbol that is specified for a category or subcategory in section 3 of Annex 3 of the GHS or for a category in Schedule 5.

Hazard statement — Specific Target Organ Toxicity — Single Exposure

(4) In the case of a hazardous product that is classified in the category “Specific Target Organ Toxicity — Single Exposure — Category 3” of the hazard class “Specific Target Organ Toxicity — Single Exposure”, the hazard statement specified for that category in section 3 of Annex 3 of the GHS that relates to the effects for which the product was classified must be used. If the hazardous product causes narcotic effects and respiratory tract irritation, as those terms are defined in Subpart 8 of Part 8, then both hazard statements must be used.

Information elements for certain categories or subcategories

(5) The information elements, namely, the symbol, signal word, hazard statement and precautionary statement, specified in section 3 of Annex 3 of the GHS that are to be used for hazardous products classified in the categories or subcategories below are as follows:

- (a) if the hazardous product is classified in the category “Flammable Gases — Category 1”, the information elements specified for the category “Flammable Gases (Including Chemically Unstable Gases)” Hazard category 1;

- (b) if the hazardous product is classified in the category “Flammable Gases — Category 2”, the information elements specified for the category “Flammable Gases (Including Chemically Unstable Gases)” Hazard category 2;

- (c) if the hazardous product is classified in the category “Flammable Aerosols — Category 1”, the information elements specified for the category “Aerosols” Hazard category 1, with the exception of the hazard statement “Pressurized container: may burst if heated”;

- (d) if the hazardous product is classified in the category “Flammable Aerosols — Category 2”, the information elements specified for the category “Aerosols” Hazard category 2, with the exception of the hazard statement “Pressurized container: may burst if heated”;

- (e) if the hazardous product is classified in the category “Skin Corrosion — Category 1”, the information elements specified for the subcategory “Skin Corrosion/Irritation” Hazard category 1A;

- (f) if the hazardous product is classified in the subcategory “Skin Corrosion — Category 1A”, in the subcategory “Skin Corrosion — Category 1B” or in the subcategory “Skin Corrosion — Category 1C”, the information elements specified for the subcategory “Skin Corrosion/Irritation” Hazard category 1A to 1C;

- (g) if the hazardous product is classified in the category “Skin Irritation — Category 2”, the information elements specified for the category “Skin Corrosion/Irritation” Hazard category 2;

- (h) if the hazardous product is classified in the category “Serious Eye Damage — Category 1”, the information elements specified for the category “Eye Damage/Irritation” Hazard category 1;

- (i) if the hazardous product is classified in the category “Eye Irritation — Category 2”, the information elements specified for the subcategory “Eye Damage/Irritation” Hazard category 2A;

- (j) if the hazardous product is classified in the subcategory “Eye Irritation — Category 2A” or in the subcategory “Eye Irritation — Category 2B”, the information elements specified, respectively, for the subcategory “Eye Damage/Irritation” Hazard category 2A or the subcategory “Eye Damage/Irritation” Hazard category 2B;

- (k) if the hazardous product is classified in the category “Respiratory Sensitizer — Category 1”, in the subcategory “Respiratory Sensitizer — Category 1A” or in the subcategory “Respiratory Sensitizer — Category 1B”, the information elements specified for the category or subcategory “Sensitization — Respiratory” Hazard category 1, 1A or 1B;

- (l) if the hazardous product is classified in the category “Skin Sensitizer — Category 1”, in the subcategory “Skin Sensitizer — Category 1A” or in the subcategory “Skin Sensitizer — Category 1B”, the information elements specified for the category or subcategory “Sensitization — Skin” Hazard category 1, 1A or 1B;

- (m) if the hazardous product is classified in the subcategory “Germ Cell Mutagenicity — Category 1A” or in the subcategory “Germ Cell Mutagenicity — Category 1B”, the information elements specified for the category “Germ Cell Mutagenicity” Hazard category 1;

- (n) if the hazardous product is classified in the subcategory “Carcinogenicity — Category 1A” or in the subcategory “Carcinogenicity — Category 1B”, the information elements specified for the category “Carcinogenicity” Hazard category 1; and

- (o) if the hazardous product is classified in the subcategory “Reproductive Toxicity — Category 1A” or in the subcategory “Reproductive Toxicity — Category 1B”, the information elements specified for the category “Reproductive Toxicity” Hazard category 1.

Pictograms

3.1. Any pictogram required to be provided on a label must, except with respect to size, be an exact reproduction of that pictogram as set out in column 3 of Schedule 3 and must,

- (a) except for the pictogram for “Biohazardous Infectious Materials”, have a black symbol on a white background with a red border in the shape of a square set on one of its points; and

- (b) in the case of the pictogram for “Biohazardous Infectious Materials”, have a black symbol on a white background with a black border in the shape of a circle.

Combined precautionary statements

3.2. (1) The precautionary statements that are required to be provided on a label may be combined if the combination contains the same information as would have been conveyed by each of the individual precautionary statements.

Non-applicable precautionary statements

(2) If a precautionary statement does not apply in a particular case with regard to the normal conditions of use, handling and storage of the hazardous product, it may be omitted.

Combined hazard statements

(3) The hazard statements that are required to be provided on a label may be combined if the combination contains the same information as would have been conveyed by each of the individual hazard statements.

Information elements of label

3.3. The pictogram, signal word and hazard statement must be grouped together on the label.

Legibility

3.4. The information elements of the label of the hazardous product or container in which it is packaged must be clearly and prominently displayed on a surface that is visible under normal conditions of use, easily legible without the aid of any device other than corrective lenses and contrasted with any other information on the hazardous product or the container.

Durability

3.5. The information elements of the label of the hazardous product or container in which it is packaged must, under normal conditions of transport and use, remain affixed to, printed or written on or attached to the hazardous product or the container and remain legible.

Specific rule — signal word

3.6. (1) If there is a requirement to provide the signal word “Danger”, any requirement to provide the signal word “Warning” does not apply.

Specific rule — hazard statement

(2) If there is a requirement to provide the hazard statement “Causes severe skin burns and eye damage”, any requirement to provide the hazard statement “Causes serious eye damage” does not apply.

Specific rule — symbol

(3) In the case of the symbols specified below, the following apply:

- (a) if there is a requirement to provide the “skull and crossbones” symbol, any requirement to provide the “exclamation mark” symbol to indicate acute toxicity does not apply;

- (b) if there is a requirement to provide the “corrosion” symbol, any requirement to provide the “exclamation mark” symbol to indicate skin or eye irritation does not apply; and

- (c) if there is a requirement to provide the “health hazard” symbol to indicate respiratory sensitization, any requirement to provide the “exclamation mark” symbol to indicate skin sensitization or skin or eye irritation does not apply.

PART 4

SAFETY DATA SHEET

Information elements

4. (1) For the purposes of paragraphs 13(1)(a) and 14(a) of the Act, the safety data sheet of a hazardous product must provide, in respect of the hazardous product, the following information elements:

- (a) the headings set out in column 1 of Schedule 1, in the order they are presented, including the corresponding item number, which is to be placed immediately before the heading;

- (b) subject to section 4.5, the content of the specific information elements set out in paragraphs 3(1)(a) and (2)(a) and (d) of Schedule 1 for the heading for item 3 and, for each heading of that Schedule, if the information is available and applicable, the content of the other specific information elements of that Schedule, including the unit of measure, if applicable, taking into account the following:

- (i) if any of the information — except that required by paragraphs 3(1)(a) and (2)(a) and (d) of that Schedule — is not available or not applicable, an indication to that effect must be clearly stated in lieu of the required specific information element, and

- (ii) in the case of a mixture, the information provided under the heading for item 11 of Schedule 1 must be information that is available on the mixture as a whole, and if information is not available on the mixture as a whole, it must be information that is available on the hazardous ingredients in the mixture, together with a clear indication of the chemical name of the hazardous ingredient to which the information pertains; and

- (c) under any applicable heading, all additional hazard information that is available with respect to

- (i) the hazardous product, and

- (ii) a product, mixture, material or substance that has similar properties, including any evidence based on established scientific principles, if that information is applicable to the normal conditions of use of the hazardous product and is not redundant, indicated alongside an identification of the product, mixture, material or substance that has similar properties.

Items 12 to 15 of Schedule 1

(2) Despite subsection (1), under each heading set out for items 12 to 15 of Schedule 1, the content of the specific information elements in that Schedule may be omitted.

Biohazardous Infectious Materials — additional information elements

(3) The following information elements must be provided, immediately following the information elements required by subsection (1), on the safety data sheet of a hazardous product that is classified in a category of the hazard class “Biohazardous Infectious Materials”:

- (a) the headings set out in Schedule 2, in the order they are presented;

- (b) under each heading, the name of each specific information element set out in column 2 in respect of that heading in the order they are presented; and

- (c) under the name of each specific information element, the content of the information element, if the information is available and applicable, including the unit of measure, if applicable, taking into account the following:

- (i) if any of the information is not available or not applicable, an indication to that effect must be clearly stated in lieu of the required information, and

- (ii) any information provided under one heading of the safety data sheet need not be repeated under any other heading.

More than one biohazardous infectious material

(4) In the case where a mixture contains more than one ingredient that is classified as a biohazardous infectious material, the information required by subsection (3) must be provided in distinct parts on the safety data sheet, sequentially, for each biohazardous infectious material.

Instructions for use — new material or substance

4.1. (1) In the case of a hazardous product for which instructions for use, provided at the time of the sale or importation, require its combination with one or more products, mixtures, materials or substances resulting in the creation of one or more new materials or substances that present one or more new or more severe hazards not already identified on the safety data sheet of the hazardous product, the safety data sheet must also provide the following information elements, in respect of each new material or substance and clearly indicate that they pertain to that new material or substance:

- (a) the nature of the new or more severe hazard; and

- (b) the content of the applicable specific information elements set out in items 4 to 11, column 2, of Schedule 1, for each corresponding heading, that is available.

Placement of information elements

(2) Despite subsection 4(1), the information elements required by subsection (1) may appear anywhere on the safety data sheet.

Identical identifiers

4.2. The product identifier and the initial supplier identifier that are provided on the safety data sheet of a hazardous product must be identical to those provided on the label.

Concentration units

4.3. If the concentration of a material or substance in a hazardous product is expressed as a percentage on the safety data sheet, the units used to calculate the percentage must be provided.

Most hazardous concentration

4.4. If ingredients in a mixture that is a hazardous product are present in a range of concentrations, the information provided on the safety data sheet must be based on data available that correspond to the most hazardous concentration of each ingredient in the mixture, whether those data pertain to an ingredient or the mixture as a whole.

Concentration ranges

4.5. If the concentration of a material or substance in a hazardous product is required to be provided on a safety data sheet and the material or substance is not always present at the same concentration, the safety data sheet must provide, in lieu of the concentration of the material or substance, the actual concentration range of the material or substance in the hazardous product.

PART 5

EXCEPTIONS

Definition of “laboratory sample”

5. (1) In this section, “laboratory sample” means a sample of a hazardous product that is packaged in a container that contains less than 10 kg of the hazardous product and that is intended solely to be tested in a laboratory, but does not include a sample that is to be used

- (a) by the laboratory for testing other products, mixtures, materials or substances; or

- (b) for educational or demonstration purposes.

Sale or importation — biohazardous infectious materials — safety data sheet

(2) Subject to subsection (3), the sale or importation of a laboratory sample that is classified only in the category “Biohazardous Infectious Materials — Category 1” is exempt from the application of paragraphs 13(1)(a) and (a.1) and 14(a) of the Act.

Transfer of possession — biohazardous infectious materials — safety data sheet and label

(3) The transfer of possession of a laboratory sample for a specific purpose, without transferring ownership, if that laboratory sample is classified only in the category “Biohazardous Infectious Materials — Category 1”, is exempt from the application of section 13 of the Act.

Transfer of possession — safety data sheet

(4) The transfer of possession of a laboratory sample for a specific purpose, without transferring ownership, if that laboratory sample is one of the following types, is exempt from the application of paragraphs 13(1)(a) and (a.1) of the Act:

- (a) a laboratory sample for which the chemical name and concentration of the hazardous product or its ingredients are not known; or

- (b) a laboratory sample for which the supplier has not offered or exposed the hazardous product for transfer of ownership.

Sale or importation — biohazardous infectious materials — label

(5) Subject to subsection (3), the sale or importation of a laboratory sample that is classified only in the category “Biohazardous Infectious Materials — Category 1” is exempt from the application of paragraph 3(1)(d) if the label provides the chemical name or generic chemical name of any material that is in the hazardous product and that is classified as a biohazardous infectious material, if known by the supplier, and the statement “Hazardous Laboratory Sample. For hazard information or in an emergency, call/Échantillon pour laboratoire de produit dangereux. Pour obtenir des renseignements sur les dangers ou en cas d’urgence, composez”, followed by an emergency telephone number for the purpose of obtaining the information that must be provided on the safety data sheet of the hazardous product.

Transfer of possession — label

(6) The transfer of possession of a laboratory sample for a specific purpose, without transferring ownership, is exempt from the application of paragraphs 3(1)(c) and (d) if the label provides the chemical name or generic chemical name of any material or substance that is in the hazardous product and that is referred to in subsection 3(2) of Schedule 1, if known by the supplier, and the statement “Hazardous Laboratory Sample. For hazard information or in an emergency, call/Échantillon pour laboratoire de produit dangereux. Pour obtenir des renseignements sur les dangers ou en cas d’urgence, composez”, followed by an emergency telephone number for the purpose of obtaining the information that must be provided on the safety data sheet of the hazardous product, and if that laboratory sample is one of the following types:

- (a) a laboratory sample for which the chemical name and concentration of the hazardous product or its ingredients are not known; or

- (b) a laboratory sample in respect of which the supplier has not offered or exposed the hazardous product for transfer of ownership.

Mixture of radioactive nuclides and non-radioactive carriers — section 13 or 14 of Act

5.1. (1) The sale or importation of a hazardous product that is a mixture of one or more radioactive nuclides and one or more non-radioactive carriers is exempt from the application of section 13 or 14 of the Act if the carrier

- (a) is present in an amount that is

- (i) in the case of a liquid or gaseous carrier, less than or equal to 1.0 ml, or

- (ii) in the case of a solid carrier, less than or equal to 1.0 g; and

- (b) is not

- (i) classified in any category or subcategory of the “Carcinogenicity”, “Germ Cell Mutagenicity”, “Reproductive Toxicity” or “Biohazardous Infectious Materials” hazard class,

- (ii) classified in the category “Acute Toxicity (Oral) — Category 1” or “Acute Toxicity (Dermal) — Category 1” of the “Acute Toxicity” hazard class, or

- (iii) classified in the category “Acute Toxicity (Inhalation) — Category 1” or “Acute Toxicity (Inhalation) — Category 2” of the “Acute Toxicity” hazard class.

Mixture of radioactive nuclides and non-radioactive carriers — paragraph 13(1)(b) or 14(b) of Act

(2) The sale or importation of a hazardous product that is a mixture of one or more radioactive nuclides and one or more non-radioactive carriers is exempt from the application of paragraph 13(1)(b) or 14(b) of the Act in respect of the requirement to have a label on the inner container of the hazardous product if the hazardous product is packaged in more than one container and the outer container has a label that provides the information elements required by Part 3.

Mixture of radioactive nuclides and non-radioactive carriers

(3) The sale or importation of a hazardous product that is a mixture of one or more radioactive nuclides and one or more non-radioactive carriers is exempt from the application of

- (a) paragraph 3(1)(b); and

- (b) paragraph 3(1)(c) and subparagraph 3(1)(d)(ii), in respect of the requirement to provide any precautionary statement on the label of the hazardous product or the container in which it is packaged.

Outer container

5.2. The sale or importation of a hazardous product is exempt from the application of paragraph 13(1)(b) or 14(b) of the Act in respect of the requirement to have a label on the outer container of the hazardous product if

- (a) the label on the inner container is visible and legible through the outer container under normal conditions of storage and handling; or

- (b) the outer container has a label that meets the requirements set out in the Transportation of Dangerous Goods Regulations.

Label — outer container — at least two hazardous products

5.3. In the case of an outer container in which at least two different hazardous products are packaged, subsection 3(1) does not apply if the label provides the following information elements:

- (a) the product identifier for each hazardous product contained in the outer container;

- (b) the initial supplier identifier;

- (c) subject to subsection 3.6(3), the pictogram set out in column 3 of Schedule 3 designated for each category or subcategory in which each hazardous product contained in the outer container is classified;

- (d) the precautionary statement applicable to the storage of each of the hazardous products contained in the outer container; and

- (e) the statement “See individual product labels for signal words, hazard statements and precautionary statements/Voir les étiquettes sur chacun des produits pour les mentions d’avertissement, les mentions de danger et les conseils de prudence”.

Small-capacity containers — 100 ml or less

5.4. (1) The sale or importation of a hazardous product in a container that has a capacity of less than or equal to 100 ml, including any subsequent container of the same capacity in which that first container is packaged, is exempt from the application of paragraph 3(1)(c) and subparagraph 3(1)(d)(i) or (ii) in respect of the requirement to provide any precautionary statement or hazard statement on the label of the hazardous product or the container.

Small-capacity containers — 3 ml or less

(2) The sale or importation of a hazardous product in a container that has a capacity of less than or equal to 3 ml is exempt from the application of section 3.5 in respect of normal conditions of use if the label interferes with the normal use of the hazardous product.

Definition of “bulk shipment”

5.5. (1) In this section, “bulk shipment” means a shipment of a hazardous product that is contained in any of the following, without intermediate containment or intermediate packaging:

- (a) a vessel that has a water capacity equal to or greater than 450 l;

- (b) a freight container, road vehicle, railway vehicle or portable tank;

- (c) the hold of a ship; or

- (d) a pipeline.

Bulk shipments and unpackaged hazardous products

(2) The sale or importation of a bulk shipment or a hazardous product without packaging of any sort is exempt from the application of paragraph 13(1)(b) or 14(b) of the Act.

Definition of “complex mixture”

5.6. (1) In this section, “complex mixture” means a mixture that has a commonly known generic name and that is

- (a) naturally occurring;

- (b) a fraction of a naturally occurring mixture that results from a separation process; or

- (c) a modification of a naturally occurring mixture or a modification of a fraction of a naturally occurring mixture that results from a chemical modification process.

Complex mixture

(2) The sale or importation of a hazardous product that is a complex mixture is exempt from the application of paragraph 4(1)(b) in respect of the requirements set out in paragraphs 3(2)(a) and (d) of Schedule 1, and in paragraphs 3(2)(b) and (c) of that Schedule, if that information is available and applicable, in relation to the ingredients of the complex mixture, if the commonly known generic name of the complex mixture is provided for item 3 of the safety data sheet.

Complex mixture — ingredient

(3) Subject to subsection (4), the sale or importation of a hazardous product that contains an ingredient that is a complex mixture is exempt from the application of paragraph 4(1)(b) in respect of the requirements set out in paragraphs 3(2)(a) and (d) of Schedule 1, and in paragraphs 3(2)(b) and (c) of that Schedule, if that information is available and applicable, in relation to the ingredients of the complex mixture if the complex mixture, individually, is classified in a category or subcategory of a health hazard class and the commonly known generic name of the complex mixture and its concentration in the hazardous product are provided for item 3 of the safety data sheet.

Concentration results in classification

(4) If the complex mixture is present at a concentration that results in the product being classified in a category or subcategory of any health hazard class further to subsection 2.5(1), the commonly known generic name and concentration of the complex mixture must be provided on the safety data sheet of the hazardous product.

Definitions

5.7. (1) The following definitions apply in this section.

“first supplier”

« premier fournisseur »

“first supplier” means a supplier who is exempted from the requirement to disclose the information specified in subsection 11(1) of the Hazardous Materials Information Review Act, by virtue of that Act.

“subsequent supplier”

« fournisseur subséquent »

“subsequent supplier” means a supplier who sells or imports a hazardous product that is the subject of an exemption granted to the first supplier from the requirement to disclose the information specified in subsection 11(1) of the Hazardous Materials Information Review Act.

Confidential information

(2) If any information is the subject of an exemption under the Hazardous Materials Information Review Act, the information must be replaced by the information required under subsection (3) or (4).

Subsection 11(1) of Hazardous Materials Information Review Act

(3) A supplier who, under subsection 11(1) of the Hazardous Materials Information Review Act, files a claim for exemption from a requirement to disclose information in respect of a hazardous product on a safety data sheet or on a label must, in respect of the sale or importation of the hazardous product, provide on the safety data sheet and, if applicable, on the label of the hazardous product or container in which the hazardous product is packaged a statement that a claim was filed, the date that the claim was filed and the registry number assigned to the claim under the Hazardous Materials Information Review Act until

- (a) in the case that an order was issued by a screening officer under subsection 16(1) or 17(1) of the Hazardous Materials Information Review Act, the end of the period that begins on the final disposition of the proceedings in relation to the claim for exemption and does not exceed the period specified in the order, as the word “proceedings” is defined in subsection 19(3) of the Hazardous Materials Information Review Act; or

- (b) in any other case, the end of the period not exceeding 30 days after the final disposition of the proceedings in relation to the claim for exemption, as the word “proceedings” is defined in subsection 19(3) of the Hazardous Materials Information Review Act.

Information to be disclosed

(4) A supplier who receives notice of a decision made under the Hazardous Materials Information Review Act that their claim or a portion of their claim for exemption from a requirement to disclose information in respect of a hazardous product on a safety data sheet or a label is valid must, during the period beginning no later than the end of the applicable period specified in subsection (3) and on compliance with any order issued under subsection 16(1) or 17(1) of the Hazardous Materials Information Review Act, if applicable, and ending on the last day of the exemption period, in respect of the sale or importation of the hazardous product, provide on the safety data sheet and, if applicable, on the label of the hazardous product or container in which the hazardous product is packaged the following information:

- (a) a statement that an exemption has been granted;

- (b) the date of the decision granting the exemption; and

- (c) the registry number assigned to the claim under the Hazardous Materials Information Review Act.

Non-application — paragraphs 3(1)(a) to (d) or (2)(a) to (c) of Schedule 1

(5) The sale or importation of a hazardous product is exempt from the application of paragraph 4(1)(b) in respect of the requirements set out in paragraph 3(1)(a) or (2)(a) of Schedule 1 and, if the information is available and applicable, in paragraphs 3(1)(b) to (d) or 2(b) and (c) of that Schedule, if it is the subject of a claim for exemption under paragraph 11(1)(a) of the Hazardous Materials Information Review Act and if the generic chemical name of the material, substance or ingredient is provided for item 3 of the safety data sheet.

Non-application — paragraph 3(2)(d) of Schedule 1

(6) Paragraph 3(2)(d) of Schedule 1 does not apply in respect of a hazardous product that is the subject of a claim for exemption under subparagraph 11(1)(b)(iii) of the Hazardous Materials Information Review Act.

Sale or importation — paragraphs 3(1)(a) to (d) or (2)(a) to (c) of Schedule 1

(7) The sale or importation of a hazardous product by a subsequent supplier is exempt from the application of paragraph 4(1)(b) in respect of the requirements set out in paragraph 3(1)(a) or (2)(a) of Schedule 1, and, if the information is available and applicable, in paragraphs 3(1)(b) to (d) or 2(b) and (c) of that Schedule, if

- (a) the first supplier is exempt from those requirements;

- (b) the information is unknown to the subsequent supplier, or the information is known to the subsequent supplier but the subsequent supplier has obtained the information in confidence, express or implied, and is obligated, expressly or implicitly, by contract or a relationship based on trust and confidence, or otherwise by law or equity, to maintain the confidentiality of the information; and

- (c) the safety data sheet for the hazardous product that the subsequent supplier provides on the sale, or obtains or prepares on the importation, provides in lieu of the information referred to in paragraph 3(1)(a) or (2)(a) of Schedule 1, and, if the information is available and applicable, in paragraphs 3(1)(b) to (d) or 2(b) and (c) of that Schedule,

- (i) the information referred to in subsection (3) or (4) in respect of,

- (A) if the subsequent supplier is exempted from the requirement to provide information that could be used to identify the first supplier, that exemption, or

- (B) in any other case, the exemption of the first supplier, with the words “other supplier/autre fournisseur” in parentheses after that information, and

- (ii) the generic chemical name of the material, substance or ingredient as provided by the first supplier.

- (i) the information referred to in subsection (3) or (4) in respect of,

Sale or importation — paragraph 3(2)(d) of Schedule 1

(8) The sale or importation of a hazardous product by a subsequent supplier is exempt from the application of paragraph 4(1)(b) in respect of the requirement set out in paragraph 3(2)(d) of Schedule 1, if

- (a) the first supplier is exempt from that requirement;

- (b) the information is unknown to the subsequent supplier, or the information is known to the subsequent supplier but the subsequent supplier has obtained the information in confidence, express or implied, and is obligated, expressly or implicitly, by contract or a relationship based on trust and confidence, or otherwise by law or equity, to maintain the confidentiality of the information; and

- (c) the safety data sheet for the hazardous product that the subsequent supplier provides on the sale, or obtains or prepares on the importation, provides in lieu of the information referred to in paragraph 3(2)(d) of Schedule 1

- (i) the information referred to in subsection (3) or (4) in respect of,

- (A) if the subsequent supplier is exempted from the requirement to provide information that could be used to identify the first supplier, that exemption, or

- (B) in any other case, the exemption of the first supplier, with the words “other supplier/autre fournisseur” in parentheses after that information, and

- (ii) subject to section 4.5, the concentration of the first supplier’s hazardous product that is in the subsequent supplier’s hazardous product.

- (i) the information referred to in subsection (3) or (4) in respect of,

Label — confidential product identifier — paragraphs 3(1)(a) and 4(1)(b)

(9) Paragraph 3(1)(a) and the requirement in paragraph 4(1)(b) in relation to paragraph 1(a) of Schedule 1, if the information is available and applicable, do not apply in respect of the sale of a hazardous product to an employer who is exempt under the Hazardous Materials Information Review Act or under the laws of a province from the requirement to disclose the product identifier of a hazardous product if the label provides a code name or code number specified by the supplier and

- (a) if available, the information referred to in subsection (3) or (4) in respect of the employer’s claim for exemption under the Hazardous Materials Information Review Act; or

- (b) if the information referred to in paragraph (a) is not available, the information required to be provided under the laws of the province.

Label — confidential supplier identifier — paragraphs 3(1)(b) and 4(1)(b)

(10) Paragraph 3(1)(b) and the requirement in paragraph 4(1)(b) in relation to paragraph 1(d) of Schedule 1, if the information is available and applicable, do not apply in respect of the sale of a hazardous product to an employer who is exempt under the Hazardous Materials Information Review Act or under the laws of a province from the requirement to disclose any information that could be used to identify the supplier of the hazardous product if that information is replaced by

- (a) if available, the information referred to in subsection (3) or (4) in respect of the employer’s claim for exemption under the Hazardous Materials Information Review Act; or

- (b) if the information referred to in paragraph (a) is not available, the information required to be provided under the laws of the province.

Safety data sheet — sale to employer

(11) The sale of a hazardous product to an employer is exempt from the requirement to disclose information on the safety data sheet that could be the subject of a claim for exemption under subsection 11(2) of the Hazardous Materials Information Review Act if

- (a) the employer is exempt, under that Act or the laws of a province, from the requirement to disclose that information in respect of the hazardous product; and

- (b) the safety data sheet of the hazardous product provided in respect of that sale provides in lieu of that information

- (i) if available, the information referred to in subsection (3) or (4) in respect of the employer’s claim for exemption under that Act, or

- (ii) if the information referred to in subparagraph (i) is not available, an emergency telephone number of the employer that will enable a health professional to obtain any information referred to in subsection 4(1) that is in the possession of the employer for the purpose of making a medical diagnosis of, or rendering medical treatment to, a person in an emergency.

Subsequent sale by supplier — safety data sheet

5.8. (1) The sale of a hazardous product by a supplier to whom the hazardous product was sold is exempt from the application of paragraph 4(1)(b) in respect of the requirement set out in paragraph 1(d) of Schedule 1 to provide the initial supplier identifier on the safety data sheet if their name, address and telephone number are provided on the safety data sheet.

Subsequent sale by supplier — label

(2) The sale of a hazardous product by a supplier to whom the hazardous product was sold is exempt from the application of paragraph 3(1)(b) in respect of the requirement to provide the initial supplier identifier on the label if their name, address and telephone number are provided on the label.

Following supplier

(3) If the initial supplier identifier referred to in subsection (1) or (2) has been replaced by the name, address and telephone number of a supplier to whom the hazardous product has been sold, any following supplier of the hazardous product may replace that information with their own name, address and telephone number.

Importation for use in own work place — safety data sheet

5.9. (1) If an importer imports a hazardous product from a foreign supplier for use in their own work place in Canada and obtains a safety data sheet from the foreign supplier, the importer is exempt from the requirement to provide, on the safety data sheet, the specific information element set out in paragraph 1(d) of Schedule 1 if the name, address and telephone number of the foreign supplier is retained on the safety data sheet.

Importation for use in own work place — label

(2) If an importer imports a hazardous product from a foreign supplier for use in their own work place in Canada, the importer is exempt from the application of paragraph 3(1)(b) in respect of the requirement to provide the initial supplier identifier on the label if the name, address and telephone number of the foreign supplier is retained on the label.

Repetition of symbols on label

5.10. The sale or importation of a hazardous product is exempt from the application of paragraphs 3(1)(c) and (d), in respect of the requirement to provide a pictogram on the label of the hazardous product or its container, if the symbol of the pictogram appears on another label in accordance with the Transportation of Dangerous Goods Regulations on that same hazardous product or that same container and if the other label also meets the requirements of section 3.5.

Safety data sheet for hazardous products — same product identifier

5.11. The sale or importation of a hazardous product is exempt from the application of paragraph 13(1)(a.1) or 14(a) of the Act in respect of the requirement to provide, or cause to be provided, a safety data sheet on the sale or to obtain or prepare a safety data sheet on or before the importation, if

- (a) the hazardous product is part of a shipment of hazardous products that have the same product identifier and a safety data sheet is obtained, prepared or provided for one of them; or

- (b) the supplier has provided to the person or government that acquires possession or ownership, or the supplier who imports the hazardous product has in their possession, a safety data sheet for a hazardous product that has the same product identifier and the safety data sheet provides, subject to section 5.12, information that is current at the time of the sale or importation.

Definition of “significant new data”

5.12. (1) In this section, “significant new data” means new data regarding the hazard presented by a hazardous product that change its classification in a category or subcategory of a hazard class, or result in its classification in another hazard class, or change the ways to protect against the hazard presented by the hazardous product.

Significant new data available within 90 days — sale

(2) The sale of a hazardous product for which significant new data became available within 90 days prior to the sale is exempt from the application of subsection 4(1) in respect of the requirement to provide, on the safety data sheet, information that is available at the time of the sale if, at the time of the sale, the supplier ensures that the person or government that acquires possession or ownership is provided with

- (a) a safety data sheet that includes all information available at the time of the sale, with the exception of the significant new data; and

- (b) the significant new data and the date on which they became available, in writing.

Significant new data available within 90 days — importation

(3) The importation of a hazardous product for which significant new data became available within 90 days prior to the importation is exempt from the application of subsection 4(1) in respect of the requirement to provide, on the safety data sheet, information that is available at the time of the importation if, at the time of the importation, the supplier

- (a) obtains a safety data sheet that includes all of the information available at the time of the importation, with the exception of the significant new data; and

- (b) obtains or prepares a document that provides the significant new data and the date on which they became available and appends that document to the safety data sheet referred to in paragraph (a).

Significant new data available within 180 days — sale

(4) The sale of a hazardous product for which significant new data became available within 180 days prior to the sale is exempt from the application of subsection 3(1) in respect of the requirement to provide, on the label, information elements for each category or subcategory of the hazard class in which the hazardous product is classified at the time of the sale if, at the time of the sale,

- (a) the hazardous product or container in which the hazardous product is packaged has a label that provides all the information elements for each category or subcategory of the hazard class in which the hazardous product is classified at the time of the sale, with the exception of the significant new data; and

- (b) the person or government that acquires possession or ownership is provided with the significant new data and the date on which they became available, in writing.

Significant new data available within 180 days — importation

(5) The importation of a hazardous product for which significant new data became available within 180 days prior to the importation is exempt from the application of subsection 3(1) in respect of the requirement to provide, on the label, information elements for each category or subcategory of the hazard class in which the hazardous product is classified at the time of the importation if, at the time of the importation,

- (a) the hazardous product or container in which the hazardous product is packaged has a label that includes all of the information elements for each category or subcategory of the hazard class in which the hazardous product is classified at the time of the importation, with the exception of the significant new data; and

- (b) the supplier obtains or prepares a document that provides the significant new data and the date on which they became available.

Transfer of possession for purpose of transportation

5.13. The transfer of possession of a hazardous product that creates a bailment for the purpose of transportation or, in Quebec, the transfer of possession of a hazardous product for the purpose of transportation, without transferring ownership, and with the obligation to deliver it to the person or government that acquired possession or ownership, is exempt from the application of paragraph 13(1)(a.1) of the Act in respect of the requirement to provide, or cause to be provided, a safety data sheet to the person to whom the possession of the product is transferred for the purpose of transportation.

Definition of “transit”

5.14. (1) In this section, “transit” means, in relation to a hazardous product, its transport through Canada after being imported and before being exported, when the place of initial loading and the final destination are outside of Canada, and, while in transport, its loading, unloading, packing, unpacking or storage.

Importation — transit

(2) The importation of a hazardous product is exempt from the application of section 14 of the Act if

- (a) the hazardous product is or is intended to be in transit; and

- (b) the hazardous product is not intended for use in a work place in Canada.

Sale — exportation

(3) The sale of a hazardous product, for the purpose of its exportation, is exempt from the application of section 13 of the Act if

- (a) the hazardous product is or is intended to be transported or, while in transport, is or is intended to be loaded, unloaded, packed, unpacked or stored, for the purpose of that sale; and

- (b) the hazardous product is not intended for use in a work place in Canada.

Importation to bring into compliance

5.15. (1) The importation of a hazardous product is exempt from the application of paragraph 14(b) of the Act if the hazardous product is imported for the purpose of being brought into compliance with the labelling requirements of these Regulations before it is used or sold.

Credible evidence

(2) A supplier who imports a hazardous product for the purpose described in subsection (1) must, on the request of an inspector, provide credible evidence to the inspector that it is being brought into compliance with the labelling requirements of these Regulations.

PART 6

ADDITIONAL REQUIREMENTS

Communication of information elements — health professionals

6. (1) A supplier who sells or imports a hazardous product intended for use, handling or storage in a work place in Canada must provide, as soon as feasible, any information element in respect of the hazardous product that is referred to in subsection 4(1) and is in the possession of the supplier to any health professional who requests that information for the purpose of making a medical diagnosis of, or rendering medical treatment to, an individual in an emergency.

Confidentiality

(2) Any information that, by virtue of an exemption under the Hazardous Materials Information Review Act or these Regulations, is not required to be provided on the safety data sheet but has nevertheless been provided by a supplier to any health professional who requests that information for the purpose of making a medical diagnosis of, or rendering medical treatment to, an individual in a medical emergency must be kept confidential, except for the purpose for which it was provided, if the health professional has been informed by the supplier that the information is to be kept confidential.

Communication of source for toxicological data

6.1. Subject to the Hazardous Materials Information Review Act, a supplier who sells or imports a hazardous product intended for use, handling or storage in a work place in Canada must disclose, as soon as feasible, the source of information for any toxicological data used in the preparation of a safety data sheet on the request of an inspector, any person or government to which the hazardous product is sold or any user of a hazardous product.

Bilingual safety data sheet and label

6.2. (1) The information elements provided on a safety data sheet and on a label must be in both official languages of Canada.

Bilingual presentation

(2) The information elements referred to in subsection (1) may

- (a) in the case of a safety data sheet, appear either on a single bilingual safety data sheet or in a document in two unilingual parts that constitute one bilingual safety data sheet; and

- (b) in the case of a label, appear either on a single bilingual label or in a group of information elements in two unilingual parts that constitute one bilingual label.

PART 7

PHYSICAL HAZARD CLASSES

SUBPART 1

EXPLOSIVES

[7.1. reserved]

SUBPART 2

FLAMMABLE GASES

Definition

Definition of “flammable gas”

7.2. In this Subpart, “flammable gas” means a gas that has a flammable range when mixed with air at 20°C and at the standard pressure of 101.3 kPa.

Classification in a Category of the Class

Exclusions

7.2.1 (1) Any product that is classified in a category of the hazard class “Flammable Aerosols” need not be classified in any category of this hazard class.

Categories

(2) A flammable gas is classified in a category of this hazard class in accordance with the following table:

TABLE

| Item | Column 1 Category |

Column 2 Criteria |

|---|---|---|

| 1. | Flammable Gases — Category 1 | A gas that

|

| 2. | Flammable Gases — Category 2 | A gas that is not classified in the category “Flammable Gases — Category 1” and has a flammable range when mixed with air |

Calculation method